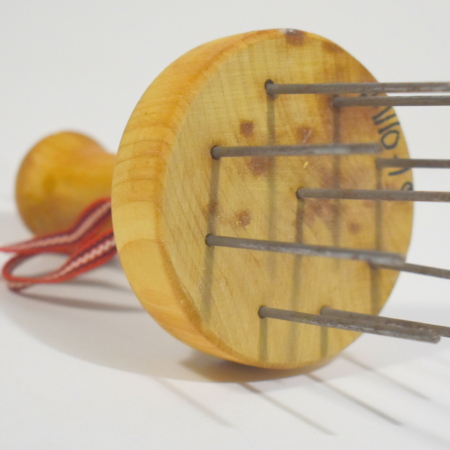

Hand Shears

This is a pair of hand shears for shearing sheep. Wool keeps sheep warm during the winter – especially on cold winter nights in Minnesota – but it is sheared in the spring for the animal’s comfort and to make clothes and blankets.

This process to shear a sheep would have taken a farmer about 20-40 minutes per sheep. The variation in time depends on how the sheep is doing, the sharpness of the shears, and the quality of the wool.

Farmers also would have had a bucket of soapy water by their workstation so they could have rinsed the shears if there was a lot of lanolin in the wool.

Pre-made fabric in the 1800s was expensive and sometimes not readily available. So, creating textiles was a necessity for many early settlers. Every step of the way – from shearing sheep to weaving fabric – was a labor-intensive process.

Here are the steps:

1. Shearing: Cut the wool off the sheep with hand shears that look like a big pair of scissors. The goal is to remove the wool in one piece. This process does not hurt the sheep.

2. Skirting and Sorting: Choose the usable wool and discard the unwanted pieces.

3. Washing: Soak/scour in hot soapy water and rinse three or four times to remove lanolin oil and heavy dirt.

4. Picking: Pull apart the fibers which releases small debris such as straw, grass, bugs, and twigs. Picking is one of the first jobs a child can do – as young as 3 or 4 years old.

5. Carding: Brush the fibers to remove the tangles and align the wool uniformly. Carding produces what’s called a rolag, or small roll, that is ready for spinning.

6. Spinning: Twist the wool fibers to form a single strand of yarn. The drop spindle can be traced back 10,000 years and are small, portable, and lightweight. The spinning wheel arrived in Western Europe during the 13th century. Because it required the spinner to sit, it is not portable. However, it produces more yarn in less time than a drop spindle.

7. Dyeing: The natural dye solution is placed in hot water and the wool skeins are submerged in the dye until the desired color is achieved. Dye colors are derived mostly from plants: leaves, flowers, nuts, bark, and roots. For instance, onion skins produce a yellow or gold color.

8. Weaving: The process of producing the cloth on a loom. Setting up the loom to weave a pattern can be a complicated process. Yarn that is attached to the loom initially is called the warp. Warping is the hardest part of weaving because threads must be measured exactly and threaded onto the loom in a certain order. Once a loom is warped, the weft threads are woven through the warp using a stick called a shuttle to create a finished piece of woven cloth.

Categories: All Artifacts, Metal Work, Tools

Tags: agriculture, farming, livestock, metal, shearing, sheep, sheep shearing, tool